Cyclone Metals Ltd (ASX:CLE) has welcomed ‘world-class’ results from the first phase of metallurgical test work conducted on its flagship Block 103/Iron Bear Magnetite Iron Ore Project in Canada.

The DR magnetite concentrate produced during the test work is set to be Cyclone’s premium magnetite ultra-low silica product, used as a feed for high-value DR pellets.

World-class results

The company engaged Corem, based in Quebec City, Canada, to complete the test work, which produced a direct reduction (DR) magnetite concentrate grading at 70.6% iron.

This material was very low in deleterious elements, with silica below 1.2%, which is an excellent result by global standards.

The DR magnetite concentrate can be produced by adding a reverse flotation stage to the company’s ‘base’ blast furnace (BF) concentrate, a simple step that can be activated or de-activated based on market conditions and customer requirements.

High recovery, high demand

What’s more, it achieved a high recovery rate – over 80% – for total iron, at a time when the estimated market price for this DR magnetite concentrate is US$167 per tonne CFR China, representing a premium of US$30 a tonne above the 62% iron benchmark.

Cyclone Metals has also optimised its process flow sheet and associated mass and energy balances have been defined and calibrated. These are essential for the pilot plant design and scoping study – both of which are underway.

Next week the company will start production of bulk samples of BF and DR magnetite concentrates using an industrial-grade pilot plant.

The company’s achievement proves that Iron Bear/Block 103 could potentially be one of a handful of iron ore producers with the capability to produce premium DR-grade concentrates.

Critical to reduce steel carbon footprint

These high-quality magnetite concentrates are critical for the steel industry to reduce its carbon footprint and are expected to replace the less fuel-efficient direct shipping ores currently produced mainly in Australia and Brazil.

Access to a large and low-cost source of DR-grade magnetite concentrate could provide a very substantial structural competitive advantage to a steel mill producing in or exporting to Europe.

Cyclone CEO Paul Berend commented: “We have achieved another very exciting milestone in the development of our flagship Iron Bear Project by demonstrating that we can easily produce a world-class magnetite DR concentrate grading 70.6% Fe, with ultra-low silica and no deleterious elements.

“If we can demonstrate that our DR concentrate is a good source material to produce DR-grade pellets, then we will be able to provide European steel producers with a realistic solution to reduce the carbon footprint of their existing blast furnace-based steel mills.

“We still have months of test work ahead of us to conclusively demonstrate this – but we will be able to provide steel mills with large bulk samples of both products as early as Q1 next year. This should enable us to start meaningful JV discussions.”

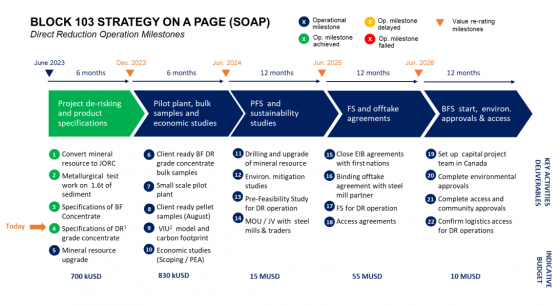

In other news, Cyclone says it remains on track to achieve its key Strategy on a Page (SOAP) operational milestones planned in calendar year 2023.

The company is working concurrently on upgrading its mineral resource in terms of size and, importantly, quality, by correlating the high-definition magnetite survey with drilling results and applying the appropriate geological constraints.

Read more on Proactive Investors AU