Volt Resources Ltd (ASX:VRC, OTC:VLTRF) welcomes the continued success of its testing program for natural graphite anode (NGA) in battery cycle life studies.

These tests, which are crucial to prove NGA's use in electric vehicle (EV) applications and many others, have been conducted since June and have yielded results that far exceed industry standards.

Long-life batteries

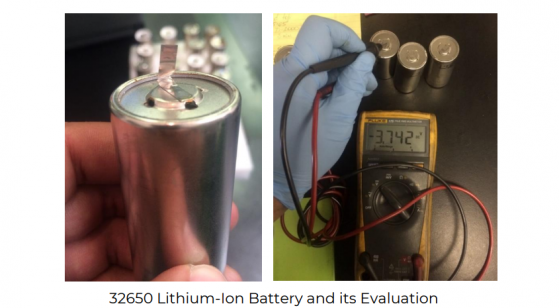

Volt's North America-based technology partner has successfully produced NGA using Volt’s high-quality natural flake graphite. This NGA was then incorporated into 32650-format lithium-ion batteries, a popular size for such applications and subjected to rigorous testing.

The batteries were cycled between 4.25 and 2.50 volts to evaluate their cycle life, a key metric for batteries in electric vehicle applications. The tests demonstrated impressive longevity, with the batteries surpassing the standard industry target of 1,000 cycles.

Extrapolated data suggests a potential cycle life of over 1,750 cycles, indicating only a 20% degradation of capacity.

The success of Volt's NGA can be attributed to its superior flake graphite and advanced purification process, which ensures the graphite contains less than 200 parts per million (ppm) impurities.

Volt's flake graphite is purified, spherodised and carbon-coated before being used as the anode material in the batteries. This meticulous process results in a product that not only exceeds performance expectations but also aligns with automotive part qualification standards, following the Production Part Approval Process (PPAP).

Demand for graphite increasing

Graphite, recognised as a critical mineral in the United States and Europe, is a major component of lithium-ion batteries, with a typical electric vehicle battery containing 50-60 kilograms of graphite.

The demand for graphite in North America for lithium-ion batteries is projected to reach 800-1,000 kilotonnes per annum by 2030. This burgeoning demand presents a significant growth opportunity for integrated NGA producers like Volt, as evidenced by the increasing interest from customers in testing and potentially adopting these products.

“More than ever, it is critical for the US and Europe to now establish an EV supply chain independent of China,” Volt managing director and CEO Prashant Chintawar said.

“We are excited about the impressive performance data of our natural graphite anode, which was produced in the US and does not rely on any Foreign Entity of Concern. We will continue to execute our customer-driven product development roadmap to bring this to the market.”

Read more on Proactive Investors AU