The recent graphite test work of Sovereign Metals Ltd (ASX:SVM, OTC:SVMLF, AIM:SVML) at four independent laboratories in Australia, Canada and South Africa has produced high-grade graphite concentrates with more than 97% total graphite content (TGC) and exceptional flotation recoveries exceeding 90%.

Frontrunner in supply for batteries

This work is being conducted as part of the company’s graphite marketing and active anode qualification strategy, supervised by Dr Surinder Ghag.

The success of the program will position the Kasiya Rutile-Graphite Project in Malawi as a frontrunner in the supply of superior-quality graphite for lithium-ion batteries.

With its highly favourable impurity profile and the ability to produce high-purity concentrates, Kasiya stands out as a potential long-term, secure source of graphite for the evolving electric vehicle and battery markets.

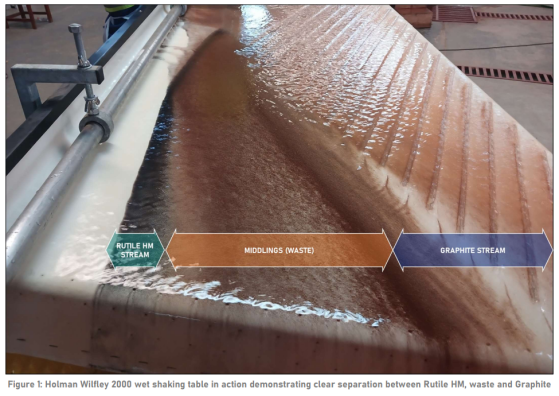

The initial graphite circuit feed was processed at Sovereign's laboratory in Lilongwe, Malawi, using a wet shaking table, which demonstrated a clear separation of rutile and graphite from waste material.

Low-cost method

This method enhances the TGC from the ore, achieving a high concentration without the need for crushing or milling – steps typically necessary for hard-rock graphite deposits. This low-cost process is unique to Kasiya’s saprolite-hosted graphite.

What’s more, the graphite concentrates indicate exceptionally low levels of sulphur compared to typical hard-rock graphite peers – a key metric to qualify as active anode material for lithium-ion batteries.

Managing director Frank Eagar said: “Our ability to upgrade Kasiya ore at 1.4% graphite to a 55% rougher concentrate without any crushing or milling, highlights more of the unique qualities of Kasiya.

“There are very limited other graphite projects with these characteristics. The pilot-scale results also confirm that Kasiya produces high-grade concentrates with very low sulphur levels at high recoveries.

“Simply put, Kasiya will be a standout producer of high-quality graphite concentrate at industry-low operating costs.”

Reduced reliance on Chinese graphite

Further downstream test work continues at German graphite consultancy ProGraphite GmbH to produce and evaluate coated spherical purified graphite (CSPG) as an active anode material.

This step is crucial for qualifying Kasiya's graphite for battery manufacturers, particularly considering its extremely low sulphur levels compared to typical hard-rock graphite peers, a critical factor in anode production.

The promising results also suggest Kasiya's potential to reduce reliance on Chinese graphite supplies, which currently dominate the market.

Read more on Proactive Investors AU