Sarytogan Graphite Ltd (ASX:SGA)’s continued scale-up of thermal purification by its American technology partner has exceeded all expectations of graphite purity.

At the heart of its current milestone success was the first purification attempt on a bulk concentrate, which elevated the graphite purity from 81.4% total graphitic carbon (TGC) to an unprecedented 99.998% carbon on a kilogram scale.

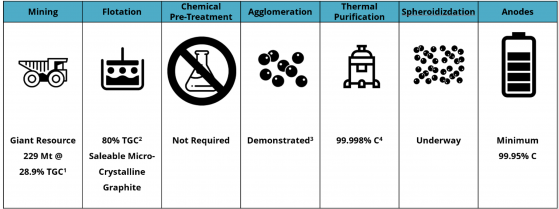

This achievement not only surpassed previous results in terms of purity and scale but also marked a notable advancement as it was accomplished without any chemical pre-treatment and at a relatively lower temperature of 2700˚C.

Building on this breakthrough, the thermally purified graphite sample is now set to undergo spheroidization. The resulting graphite spheres are intended for use in lithium-ion batteries, while the high-purity fine by-product is earmarked for various advanced industrial applications.

These applications can be used for multiple types of batteries, contingent upon successful product qualification.

Alongside these technical advancements, Sarytogan is also making steady progress with its pre-feasibility study (PFS). This study, integral to the project's advancement, is on track for completion by no later than the third quarter of 2024.

“This result has surprised on the upside with the Sarytogan Graphite achieving ultra-high purity of 99.998% even at the larger kilogram scale, lower 2,700 degree Celsius temperature and by-passing the chemical pre-treatment previously applied,” Sarytogan managing director Sean Gregory said.

“Spheroidization of this sample will now commence ahead of battery testing for lithium-ion and many other battery types.”

Thermal Purification

Sarytogan’s American technology partner received the bulk flotation concentrate at 81.4% TGCc. The concentrate was then successfully agglomerated as previously reported ahead of thermal purification.

The thermal purification process achieved a groundbreaking purity level of 99.998% carbon, surpassing all expectations. This achievement is notable for three key reasons:

Firstly, this high purity was attained without the need for chemical pre-treatment. The earlier result of 99.990% was achieved on a sample already chemically purified to 99.70%. By eliminating this step, the process not only becomes simpler but also reduces the cost base for the project, as shown below.

Thermal Flowsheet for the Sarytogan Graphite Project. Note the Chemical Flowsheet is also being separately developed as an option.

Secondly, the process utilised a temperature of 2,700 degrees Celsius, which is significantly lower than the previous 3,000 degrees. This reduction is substantial in terms of both the energy required and the reduced wear on the furnace lining, leading to noteworthy cost savings.

Thirdly, the scale of this test was considerably larger, involving 1.1 kilograms of graphite compared to just 50 grams in the previous test. Scaling up often carries the risk of decreased performance, yet in this case, the process not only maintained but actually improved its efficiency and results. This advancement is a critical milestone in demonstrating the scalability and effectiveness of the thermal purification process.

What’s next?

The spherodization process has now begun in North America.

Following this, battery testing is set to start early next year. Depending on the outcomes of the battery testing and subsequent product qualification, these graphite spheres are intended for use in the lithium battery market.

Additionally, the high-purity fine by-product derived from this process is aimed at a variety of advanced battery systems currently in commercial use. These systems include alkaline, lithium primary, lead-acid, and metal-air batteries, as well as electrochemical supercapacitors, which are crucial in most start-stop vehicles.

Meanwhile, an alternative method involving chemical purification is being developed in Germany. This advancement plays a crucial role in informing the ongoing PFS, which is on track for completion by the third quarter of 2024. This step marks a significant development in the project, potentially broadening the application of the thermally purified graphite in various battery technologies.

Read more on Proactive Investors AU