Cyclone Metals Ltd (ASX:CLE) has passed a key milestone with pilot plant test work for the Iron Bear Project in Canada delivering iron ore concentrates with high purity and yield, essential for green steel production.

The test work at the company’s flagship magnetite project marks a pivotal development in advancing large-scale sustainable steel manufacturing.

Improved met test results

During the Phase 1 metallurgical test work, around 500 kilograms of source sediment with a 29.1% total iron (Fe) content was processed, yielding a Direct Reduction (DR) concentrate grading 71.3% Fe and 1.1% silicon dioxide (SiO2), surpassing previous results.

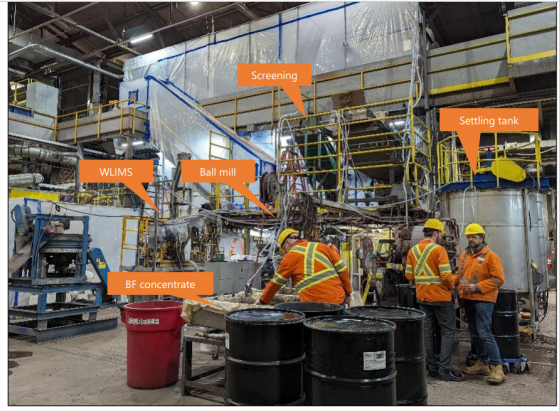

Pilot plant in operation at Corem, Quebec City.

This high-grade DR concentrate is critical for steel production via Direct Reduction technologies, supporting the shift towards more environmentally friendly production practices.

Additionally, the plant produced a Blast Furnace concentrate grading 69.8% Fe and 3.4% SiO2 and a Reverse Flotation (RF) concentrate with 68.3% Fe and 4% SiO2, further enhancing overall recovery rates and product quality.

The low levels of deleterious elements in all products underscore the project's potential to deliver clean, high-quality inputs for steelmaking.

Economic viability

The Iron Bear Project, near Schefferville on the border between Newfoundland and Labrador and Quebec, benefits from proximity to key infrastructure, including an open-access heavy haul railway directly linked to major iron ore export ports.

The nearby Menihek hydro-plant provides potential access to renewable energy, significantly bolstering the project's economic viability.

An updated mineral resource estimate by Burnt Shirt Pty Ltd stands at 16.6 billion tonnes of iron (Fe) grading 29% total Fe and 18.2% magnetic Fe, as of April 2024, classified under the Australian Joint Ore Reserves Committee (JORC) standards.

The substantial resource, combined with advanced pilot plant test work, positions Cyclone Metals at the forefront of developing the next generation of low-carbon iron ore products.

Looking ahead, Cyclone has initiated Phase 2 of the pilot program, aiming to produce larger sample sizes for further metallurgical testing and potential client trials, demonstrating the project's capability to meet industrial-scale demands and fostering partnerships for future off-take agreements.

“Exceptional properties”

CEO Paul Berend said: "The first phase of the pilot test work confirms the exceptional metallurgical properties of the Iron Bear deposit.

“We were able to produce one of the highest quality magnetite concentrates in the world with very high yields in an industrial setting.

“We are now in a position to supply ultra-high quality iron ore product samples to steel mills and trading houses, and then start offtake/JV discussions. These are exciting times.”

Read more on Proactive Investors AU